Scientists have developed a way to dramatically reduce the cost of recycling certain electronic waste by using whey protein.

Their method allows for the easy recovery of gold from circuit boards at a cost of energy and materials amounting to 50 times less than the price of the gold they recover—these are the numbers that big business likes to see.

Indeed, the potential for scalability depends on this sort of cost savings, something traditional e-waste recycling methods just can’t achieve.

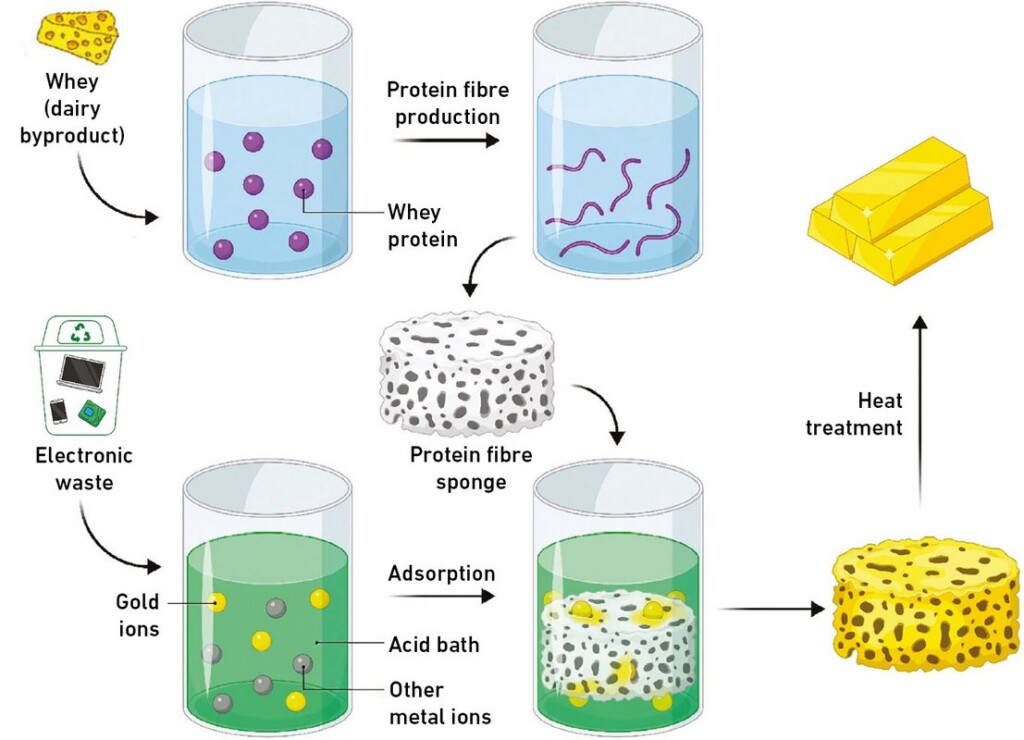

Professor Raffaele Mezzenga from ETH Zurich has found that whey protein, a byproduct of dairy manufacturing, can be used to make sponges that attract trace amounts of ionized gold.

Electronic waste contains a variety of valuable metals, including copper, cobalt, and gold. Despite gold’s public persona as being either money or jewelry, thousands of ounces of gold are used in electronics every year for its exceptional conductive properties.

Mezzenga’s colleague Mohammad Peydayesh first “denatured whey proteins under acidic conditions and high temperatures, so that they aggregated into protein nanofibrils in a gel,” writes the ETH Zurich press. “The scientists then dried the gel, creating a sponge out of these protein fibrils.”

The next step was extracting the gold: done by tossing 20 salvaged motherboards into an acid bath until the metals had dissolved into ionized compounds that the sponge began attracting.

Removing the sponge, a heat treatment caused the gold ions to aggregate into 22-carat gold flakes which could be easily removed.

“The fact I love the most is that we’re using a food industry byproduct to obtain gold from electronic waste,” Mezzenga says. In a very real sense, he observes, the method transforms two waste products into gold. “You can’t get much more sustainable than that!”

They were able to extract 450 milligrams or around $38.70 worth of fine gold at current market value. The real value would be slightly lower because their nuggets were about 9% copper. Further smelting could remove the copper, but it would be a bit less than 450 mg.

However, the real dollar value comes from the bottom line—which was 50 times more than the cost of energy and source materials. Because of this, the scientists have every intention of bringing the technology to the market as quickly as possible while also desiring to see if the protein fibril sponge can be made of other food waste byproducts.

E-waste is a quickly growing burden in global landfills, and recycling it requires extremely energy-intensive machinery that many recycling facilities do not possess.

YOU’VE GOTTA CHECK OUT: 580 Repair Shops Form a Flourishing Subculture Fixing Toasters, Electronics, Coffee Makers, and Lamps

The environmental value of the minerals contained within most e-waste comes not only from preventing the hundreds of years it takes for them to break down in the soil, but also from the reduction in demand from new mining operations which can, though not always, significantly degrade the environments they are located in.

Other countries are trying to incentivize the recycling of e-waste, and are using gold to do so. In 2022, GNN reported that the British Royal Mint launched an electronically traded fund (ETF) with each share representing the value of gold recovered from e-waste as a way for investors to diversify into gold in a way that doesn’t support environmentally damaging mining.

MORE E-WASTE RECYCLING: America’s Largest Solar Panel-Maker Leads the World in Panel Recycling–Recovering 95% of Materials

The breakthrough is reminiscent of that old fairy tale of Rumpelstiltskin who can spin straw into gold. All that these modern-day, real-life alchemists are doing differently is using dairy and circuit boards rather than straw.

SHARE This Real-Life Alchemy With Your Friends Who Hate Throwing Electronics Away…

– **Innovative Recycling Technique**: The use of whey protein to extract gold from electronic waste presents an innovative and sustainable recycling technique that significantly reduces costs.

– **Environmental Impact**: This method not only helps in recovering valuable metals but also addresses the growing burden of e-waste in landfills while reducing the need for new mining operations.

– **Market Potential and Expansion**: The successful extraction of gold through this method opens up opportunities for market adoption and potential utilization of other food waste byproducts for similar recycling processes. This highlights the scalability and broader environmental impact of the technology.