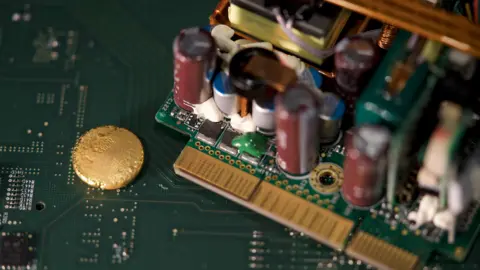

BBC/Kevin Church

BBC/Kevin ChurchThe company has built a large industrial plant on its site in Llantrisant in Wales to remove the precious metal from old circuit boards.

The gold is initially being used to craft jewellery and later it will be made into commemorative coins.

E-waste, which includes anything from old phones and computers to TVs, is a rapidly growing problem – the UN says 62m tonnes were thrown away in 2022.

Its latest report estimates that the mountain of discarded tech is set to increase by about a third by 2030.

### Urban Mining at The Royal Mint

The Royal Mint plant in Wales is pioneering urban mining by extracting gold from e-waste circuit boards. This innovative approach not only addresses the issue of electronic waste but also utilizes valuable resources that would otherwise go to waste.

At the Royal Mint plant, piles of circuit boards are being fed into the new facility.

First, they are heated to remove their various components. Then the array of detached coils, capacitors, pins and transistors are sieved, sorted, sliced and diced as they move along a conveyor belt.

Anything with gold in it is set aside.

“What we’re doing here is urban mining,” says head of sustainability Inga Doak.

“We’re taking a waste product that’s being produced by society and we’re mining the gold from that waste product and starting to see the value in that finite resource.”

### Sustainable Gold Recovery Process

The process at the Royal Mint involves extracting gold from old circuit boards in a sustainable and eco-friendly manner. Unlike traditional gold recovery methods that are energy-intensive and use toxic chemicals, the Mint’s innovative approach utilizes a chemical solution at room temperature, reducing energy consumption and environmental impact.

The gold-laden pieces go to an on-site chemical plant.

They’re tipped into a chemical solution which leeches the gold out into the liquid.

This is then filtered, leaving a powder behind. It looks pretty nondescript but this is actually pure gold – it just needs to be heated in a furnace to be transformed into a gleaming nugget.

“Traditional gold recovery processes are very energy intensive and use very toxic chemicals that can only be used once, or they go to high energy smelters and they’re basically burnt,” says Leighton John, the Royal Mint’s operations director.

“The ground-breaking thing for us is the fact that this chemistry is used at room temperature, at very low energy, it’s recyclable and pulls gold really quickly.”

### Diversification and Job Preservation

The Royal Mint’s shift into e-waste processing signifies a strategic move to diversify its operations and create new revenue streams. By repurposing electronic waste and recovering valuable materials like gold, the Mint not only contributes to sustainability but also ensures job retention in a changing economic landscape.

As well as recovering gold, the company is also looking at what to do with all of the other materials that it is separating out from the circuit boards.

They contain a number of different materials including aluminium, copper, tin and steel. They’re also investigating whether ground up boards could be used by the construction industry.

:max_bytes(150000):strip_icc():focal(999x0:1001x2)/hailey-bieber-8-78a1cb22bcb7468fa6a544f4ba591eb7.jpg?w=120&resize=120,86&ssl=1)